Site Search

Search within product

第757号 2024 (R06) .01発行

Click here for PDF version

農業と科学 令和6年1月

本号の内容

§ジェイカムアグリがなすべき事

Jcam Agri Co.

営業統括本部長 河村 光太郎

§コーティング肥料マイスター細粒の芝地における肥料効果試験

一般財団法人 関西グリーン研究所

所長 森 将人

§土のはなし-第28回

農業と環境問題-その3

農地由来の窒素による大気汚染-アンモニア揮散

前 ジェイカムアグリ株式会社

北海道支店 技術顧問

松中 照夫

What JCAM Agri should do

Jcam Agri Co.

営業統括本部長 河村 光太郎

Happy New Year!

We would like to take this opportunity to thank you for reading "Agriculture and Science.

At the beginning of the year 2024, I would like to offer a few words.

As you are well aware, the fertilizer industry has experienced price volatility over the past several years, mainly due to raw material prices.

The abnormal price hikes of raw materials continued due to the global unrest in Ukraine and other countries, China's policy of prioritizing its own country, and the continued depreciation of the yen. Although there have been similar cases in the past (the oil shocks in the 1970s and the world food crisis in 2008), I believe that the difference between "having or not having things" was one of the reasons for the rise in raw material prices this time.

Although prices of various raw materials are now lower than at the peak, the global environment for fertilizer raw materials has not changed significantly, and the future remains unpredictable.

In any case, we were made keenly aware of "the harshness of not being able to procure goods domestically and not being able to own things.

In this environment, the industry experienced major changes in distribution due to price fluctuations, and we were pressed to respond to these changes.

On the contrary, since the second half of the last fiscal year, when prices began to decline, cargo movements have slowed down completely, and the current fiscal year has been very difficult. I have been in the business for about 16 years, and at that time, I used to make product allocation based on the feeling of "about the same level as the same month of the previous year," and the results were not so far off, but that method is not applicable at all now.

However, this is not the way it should be.

What we are looking for now is "on-site ability. The goal of sales work is to increase sales, and the field skills needed to reach that goal are "information gathering," "improvement of technical skills," "networking," "handing over to the next generation," and, I believe, "analytical skills" necessary for demand forecasting.

We believe that there is probably still inventory in circulation in various places today, and we believe that we will be able to determine to some extent how much demand has been distributed by making full use of this analysis capability.

However, it is difficult for us to grasp the inventory situation in the entire prefecture by ourselves, so we would appreciate your advice to our sales staff as we will continue to forecast demand and conduct appropriate production, while receiving important information from the people who are usually our customers.

As a pioneer in the field of coated fertilizers, we will continue to do our utmost to control the outflow of coated shells. We are currently working to promote the use of "J Coat," which has a lower resin ratio than LP Coat, but unfortunately we cannot reduce the resin ratio to zero in order to ensure sigmoid elution that is almost the same as that of LP Coat.

However, with the recognition that "J Coat" is not a goal but a starting line, we are steadily moving in the direction of resin reduction, and new technologies are being considered not only in-house but also with external research partners.

We will continue to work as one to provide you with a good report as soon as possible, and we look forward to your continued guidance and encouragement.

Lastly, I would like to conclude my New Year's greeting by asking for your continued patronage of this issue of "Agriculture and Science" and wishing you a happy and prosperous new year.

Coating Fertilizer Meister Fine Granules

芝地における肥料効果試験

一般財団法人 関西グリーン研究所

所長 森 将人

1. golf course turf and manure management

(1) Differences in the type of lawn and where it is used.

Turf varieties used on golf courses in the Kansai region generally consist of bentgrass and koulaishiba for greens, koulaishiba (scientific name: Zoysia pacifica) for teeing grounds and fairways, and noshiba (scientific name: Zoysia japonica) for roughs, while non-green areas are The rest of the field is composed of warm-season turfgrasses. The Japanese pampas grass used on the greens is called "Japanese pampas grass," and its leaves are thinner than those of the Japanese pampas grass used on fairways, etc., and it is used in a lower mowing environment.

Warm-season turfgrass is characterized by new leaves (sprouts) that emerge around April, grow through the summer, turn brown in late fall, and stop growing in winter. This is the reason why turf grass looks brown in winter on golf courses. Some golf courses use coloring agents to make the grass look green as an evergreen effect, in order to make the boundary between fairways and roughs clear.

(2) Lawn fertilization

Fertilizer management on golf course turf can be broadly classified into two categories: greens and non-greens. In particular, the current fertilizer management of greens is divided into two main categories: greens and non-greens. The reason for this change is that the tendency to reduce the amount of fertilizer (mainly nitrogen) applied at one time has changed, and instead of promoting rapid turf growth, fertilizer management has shifted to minimizing uneven growth through frequent application of fertilizer.

On the other hand, as for fertilizer management of fairways and rough terrain, granular chemical fertilizers are generally applied in spring and fall, and teeing grounds may be fertilized more frequently and in larger quantities because they are often damaged by wear and tear per area and shots. The amount of fertilizer to be applied at one time would be about 3-5 g/m2 of nitrogen.

2. various tests on the use of Meister fine granules on turf

Many golf courses use fast-acting chemical compound fertilizers, which are easy to release. In other cases, urea is used for cost reasons, and coated fertilizers are used to maintain the fertilizing effect by gradually dissolving the fertilizer. In this study, we conducted tests using Meister fine granules (coated urea fine granules), which is classified as a coated fertilizer, to confirm the growth on lawns and to confirm yield during post-fertilization management.

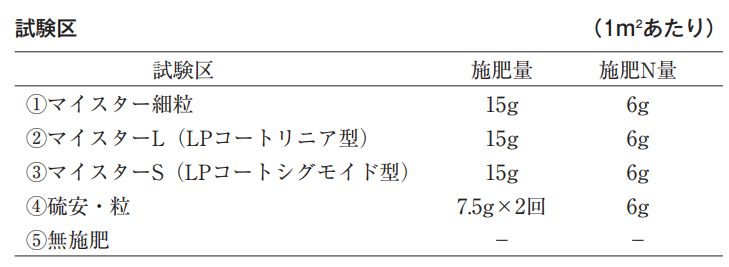

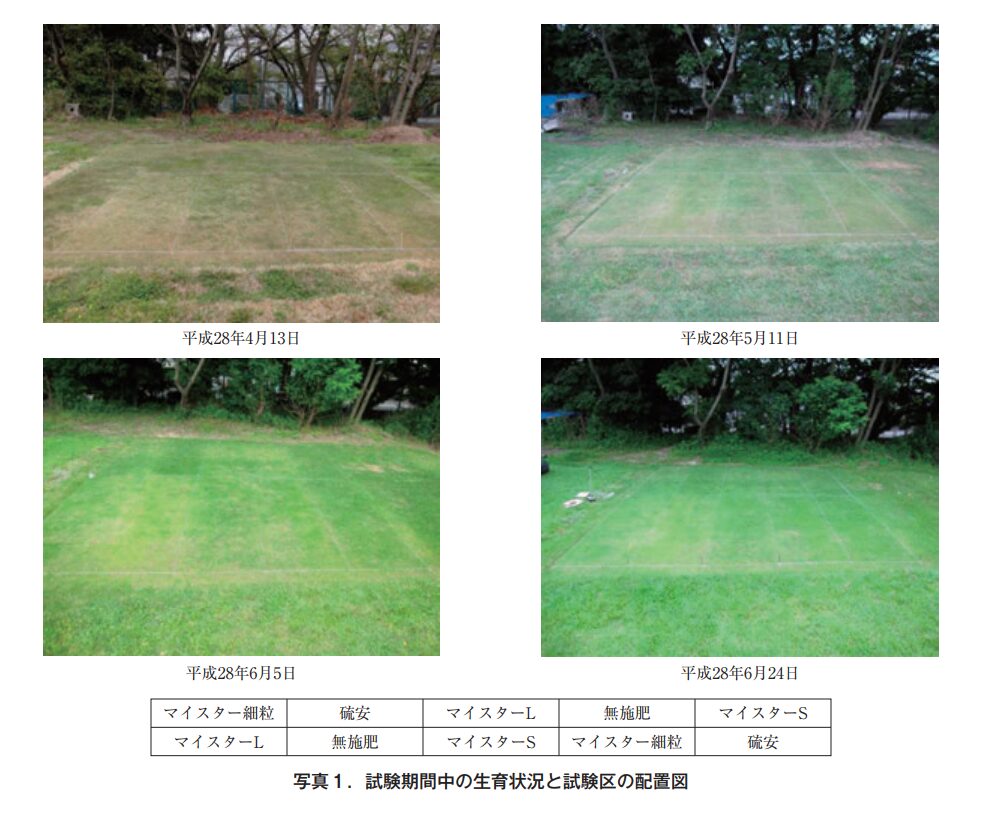

(1) Korai Shiba growth test on Meister fine granules

The main purpose of this study was to assess the growth of turfgrass in the following spring and beyond by applying various types of fertilizers as fall fertilizers to a test site of white clover.

Confirmation and, in particular, whether the Meister fine granules elute as intended.

<Test Method

Test site: Kansai Green Research Institute, Kouraishiba test plot

Testing period: October 6, 2015 - June 24, 2016

Scale: 1m x 3m = 3m2 per plot 2 iterations

Turfgrass: Kouraishi Birch (used on teeing grounds and fairways)

Floor soil: Masago soil

Management: Mowing height 13mm by green mower, mowing frequency 1 time/week

Survey items: (1) Leaf color survey (measurement of NDVI value)

(2) Above-ground growth volume survey (measurement of harvested dry weight)

(3) Photographic documentation

<Test Results and Discussion

The kouraishiba plots were cut on October 6, 2015, and fertilizer was applied after the NDVI of each test plot was measured. The ammonium sulfate fertilized area was fertilized a second time on April 14, 2016.

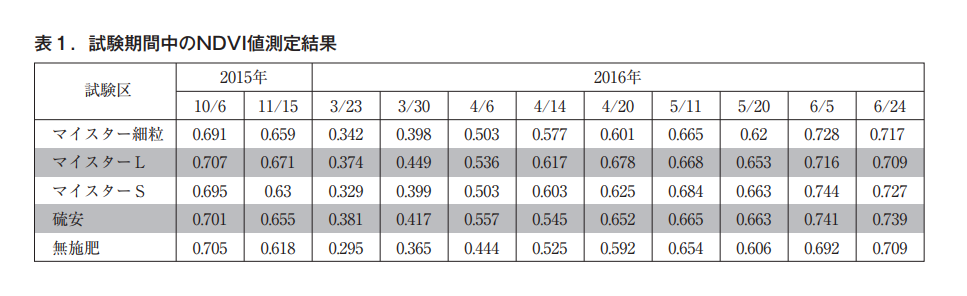

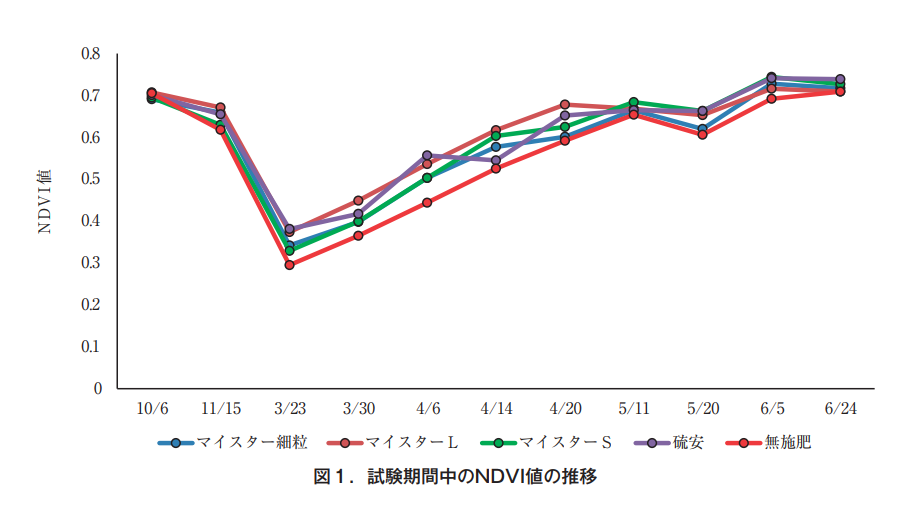

The results of the leaf color change study (NDVI values), measured immediately after the start of the test until the end of the test, are shown in Table 1 and Figure 1.

Leaf color surveys around March and April 2016 showed that Meister fine grains and Meister S had slightly lower greenness than Meister L and ammonium sulfate, but Meister S had the highest greenness from May onward.

The greenness of Meister fine grains was lower than that of the other fertilizer treatments from March to May. This may be due to the fact that it took some time for the fertilizer effect to appear.

The greenness of Meister L was highest at the time of the survey on April 20, and tended to decrease gradually from May onward.

The study of the growth of common reedgrass was conducted by examining the amount of above-ground clippings since April, 2016. That is, each test plot was periodically mowed with a green mower, and the clippings were weighed after drying at 80°C for 24 hours.

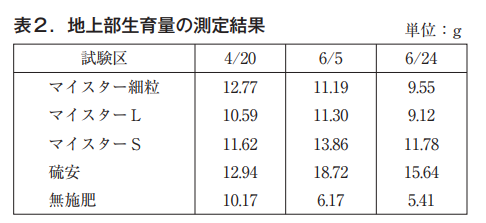

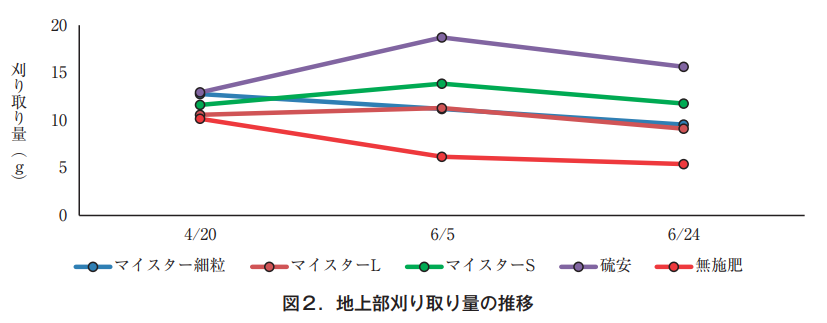

According to the results of the crop yield survey shown in Table 2 and Figure 2, there was no significant difference in the fertilizer-applied areas except for the no-fertilizer area when the survey was conducted on April 20, but after the second application of ammonium sulfate on April 14, the amount of growth of ammonium sulfate increased.

In the comparison of Meister fine grain, Meister L, and Meister S, Meister S was slightly superior in terms of growth rate, but the difference was not so pronounced. The results showed that the performance of Meister L and Meister S as fertilizers was not at all problematic, since each showed a clear improvement in greenness and growth rate compared to no fertilizer application from June onward.

(2) Meister fine grain yield test by control machine

A possible problem when granular fertilizers such as coated fertilizers and chemical fertilizers are applied to fairway and rough turf is the possibility that fertilizers may also be collected by sweeper operations for mowing and collecting clippings and fallen leaves after fertilizer application. Although conditions vary depending on the mowing height and turf density of the lawn, we confirmed the amount of fertilizer that is taken away by the machine after fertilizer application in the white clover and noshiba plots.

<Test Method

Test product: Meister Fine Granules (tentative name) 40-0-0 Particle size 1.93 mm (tentative)

Test site: Kansai Green Research Institute

Kouraishiba test plot (mowing height: 13 mm, mowing frequency: 1 time/week)

Noshiba test plot (mowing height 50mm, mowing frequency 1 time/2 weeks)

Test fertilizer:

(1) Meister fine granules (particle size 1.93 mm (tentative))

(2) Meister (sigmoid) grain size 2.0-4.0 mm

Test date: Date of fertilizer application, October 5, 2015

Mowing and sweeper work days - October 6, 2015 and October 20, 2015 (mowing work only)

Fertilizer amount: 50 g/m2 each

Management conditions: Both koulaishibai and noshibai are set

(The mowing height is about 15 mm for the koulaishiba and 50 mm for the noshiba.

<Survey Methodology

Fertilizer was applied the day before the mowing and sweeper operations, and the mowing and sweeper operations were conducted the following day. After each operation, the weight of fertilizer collected was measured.

<Test Results and Discussion

Fertilizer was applied on October 5 in the Korai shiba and Noshiba test plots to conduct the test (Photo 2). On the following day, October 6, mowing and sweeping were conducted.

The test plot was mowed with a 13mm mower made by Tsuchiya, and the weight of fertilizer collected in the bucket was measured (Photo 3). A similar mowing operation was conducted on October 20 in the same test plot. The results are shown in Table 3.

Sweeper operations were conducted in the kouraishiba and noshiba test plots. A Baroness green sweeper was used for the operation, and the weight of the fertilizers taken away in each test plot was measured. The results are shown in Table 4.

In the mowing operations shown in Table 3, there was fertilizer deprivation when mowing was done immediately after fertilizer application, but only a little deprivation when mowing was done 14 days after fertilizer application. Since mowing immediately after fertilizer application is not done under normal management, we believe that mowing after a few days of fertilizer application would have little problem with depredation.

In the sweeper operation shown in Table 4, the amount of yield was particularly high in the white buckwheat test plot. The reason for this is thought to be the use of a sweeper for greens, which increased depredation due to the high ground pressure of the brush. It is not impossible to reduce the amount of fertilizer deprivation by lowering the ground pressure of the machine (reducing the amount of mowing debris deprivation), but it is also necessary to (1) mow more frequently within one month after fertilizer application, mow before the grass grows longer, and avoid using the sweeper to reduce the amount of mowing debris, and (2) apply fertilizer after the last mowing of the year. (2) Fertilizer application after the last mowing of the year.

3. end

Fertilization is an essential part of golf course turf management as a place to enjoy golf play. Although it is desirable to provide turf in as good a condition and quality as possible, the price of fertilizers has been rising since around 2021, and some golf courses are either not applying fertilizer to areas such as rough slope surfaces or reducing the amount of fertilizer applied at one time. If fertilizer has been applied continuously for many years, even if spring and fall fertilization is reduced to fall only, it will not cause a drastic decline in turf quality, but if no fertilization is continued for three or five years, it will cause problems in the landscape and golf play.

In addition, the number of maintenance workers is getting older each year, and it is difficult to recruit new workers, which makes it difficult to make progress in maintenance work. In order to reduce the amount of fertilizer applied to the fairways and roughs, it is effective to apply slow-release fertilizers in the fall, and if the fertilizer effect is maintained until the following year before the rainy season, the spring fertilizer application can be eliminated.

Although there are some negative aspects to the successful use of these fertilizers, such as yield problems as tested and weed growth due to the dissolution of fertilizer components even during the winter season, it would be good to have turf management that matches the fertilizers, such as fertilizer application after mowing around November and thorough winter weed control.

No Soil - No. 28

農業と環境問題-その3

農地由来の窒素による大気汚染-アンモニア揮散

前 ジェイカムアグリ株式会社

北海道支店 技術顧問

松中 照夫

Livestock production in Japan has developed through dependence on imported concentrate feed. This has been the result of policy inducements since the end of World War II. This trend remains unchanged to this day, and the feed self-sufficiency rate is extremely low at 26%. Dependence on imported feed makes it possible to run a livestock business even if the farmland to produce feed for livestock is small. Thus, livestock production detached from the land increased the number of head of cattle raised, regardless of the area of land used for management. However, this means that instead of using the manure excreted daily by livestock as an important source of nutrients, it is likely to become a source of environmental pollution by dumping large amounts of manure on small farmlands.

Continuing from last month, this month we consider the environmental problems caused by ammonia volatilization of nitrogen (N), especially N derived from livestock manure, leaking from agricultural lands into the environment.

1. negative environmental impact of volatilized ammonia

Ammonia-form nitrogen (NH4-N) in livestock manure volatilizes into the atmosphere as ammonia gas (NH3) when exposed to the atmosphere, as it does when given to grassland surfaces.

NH3 volatilization is not only a loss of N as a fertilizer nutrient, but also a source of stronger acid rain because the volatilized NH3 combines with sulfur oxides, nitrogen oxides, and chlorides in the atmosphere and falls as rain containing sulfuric acid, nitric acid, and hydrochloric acid. The NH4-N thus deposited has a major adverse effect on the environment by disrupting the growth of trees and other plants, and by penetrating into the soil and undergoing nitrate conversion, lowering the pH of the soil and worsening the nutrient balance of the soil.

Even when chemical fertilizers are applied to the soil surface, NH3 volatilization is low and can be detected only slightly with urea, unless the soil is particularly alkaline. In addition, when livestock manure is covered by soil as little as 2 cm thick, NH3 volatilization is almost nonexistent (Matsunaka et al., 2008).

2. NH3 volatilization from livestock manure applied to grassland surfaces and related factors

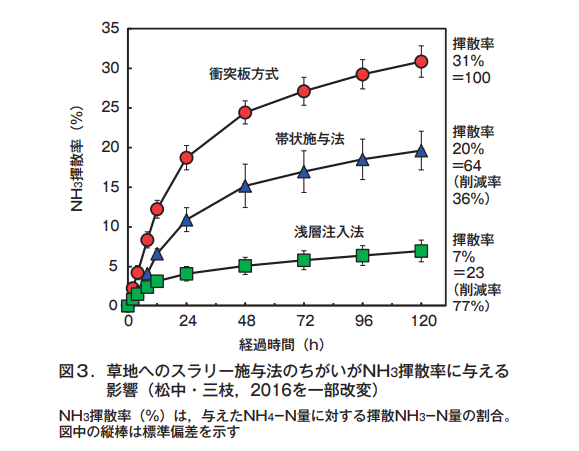

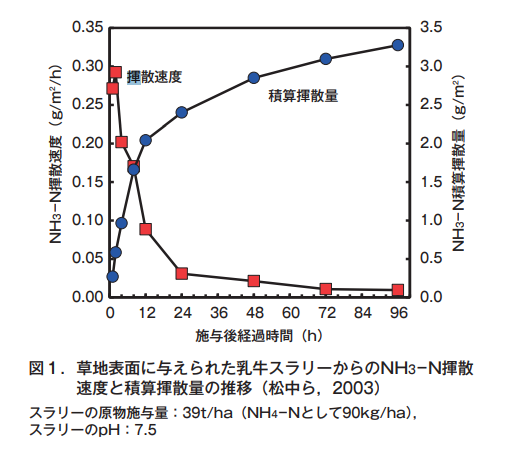

Peak NH3-N volatilization per unit time (NH3-N volatilization rate) from livestock manure applied to grassland surfaces generally appears within a few hours after application, and NH3 volatilization is completed within a few days (Figure 1).

The ratio of the amount of volatilized NH3-N to the given amount of NH4-N is called the ammonia volatilization rate (hereafter referred to as NH3 volatilization rate). When dairy cow slurry (a mixture of feces and urine excreted by dairy cows plus bedding material such as sawdust) is fed to the grassland surface, the ammonia volatilization rate is about 30% if the amount of slurry fed is up to 60 t/ha (Matsunaka et al., 2008).

The NH3 volatilization rate increases with the pH and dry matter content of the slurry and with the temperature at the time of feeding. However, when the soil is dry, the volatilization rate decreases because NH4-N in the slurry can easily penetrate into the soil. Of these factors, temperature has the greatest effect on NH3 volatilization (Matsunaka et al., 2002).

3. measures to control NH3 volatilization from livestock manure applied to grassland surfaces

It is virtually impossible to completely prevent NH3 volatilization from livestock manure applied to grassland or soil surfaces unless there is a large amount of rainfall after the application. However, if the manure is fed in a way that prevents it from coming into contact with the atmosphere, the volatilization rate can be reduced.

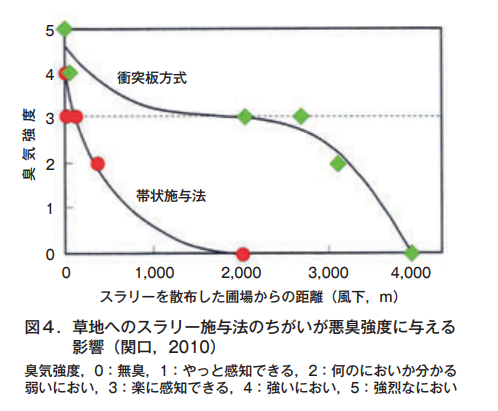

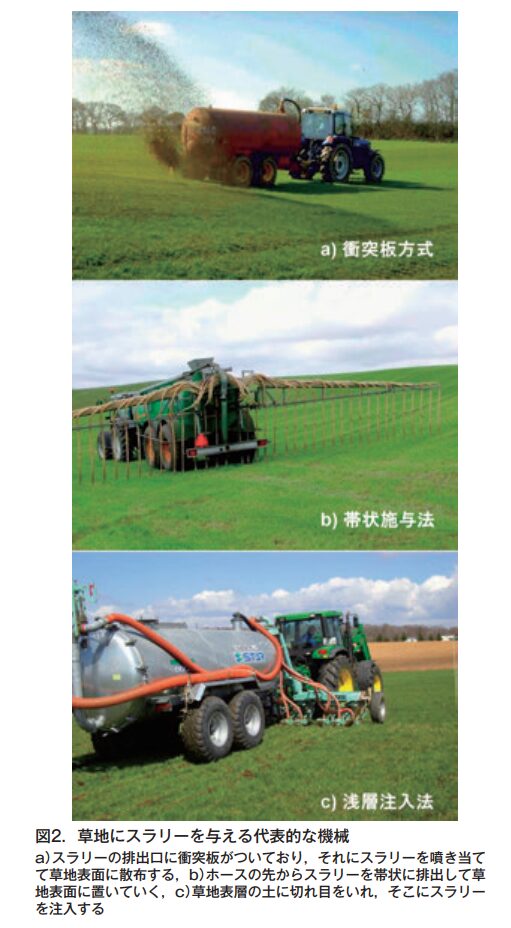

For example, the methods used to apply dairy slurry to grassland surfaces include the impact plate method (splash plate, Figure 2-a), band spread method (band spread, Figure 2-b), and shallow injection method (shallow injection, Figure 2-c). Figure 2-c). Of these, the collision plate method is commonly used in Japan. This method has the highest NH3 volatilization rate compared to the other methods because the slurry is more easily exposed to air (Figure 3). Compared to this method, the shallow injection method reduces volatilization loss by 77%, and the zonal application method not only reduces volatilization loss by 36%, but also has a significant effect on reducing the odor intensity after manure application (Figure 4).

As mentioned last month, the European Union (EU), which is actively working to curb environmental pollution caused by agriculture, has legally regulated the amount of manure-derived N applied to agricultural land to a maximum of 170 kg/ha. In addition, in order to control NH3 volatilization, which has a large negative impact on the environment, the use of dairy cattle slurry sprayed by the impact plate method, which has a high volatilization rate and a strong odor, is prohibited. In Japan, the problem of environmental pollution by livestock manure continues in the absence of such strong regulations.